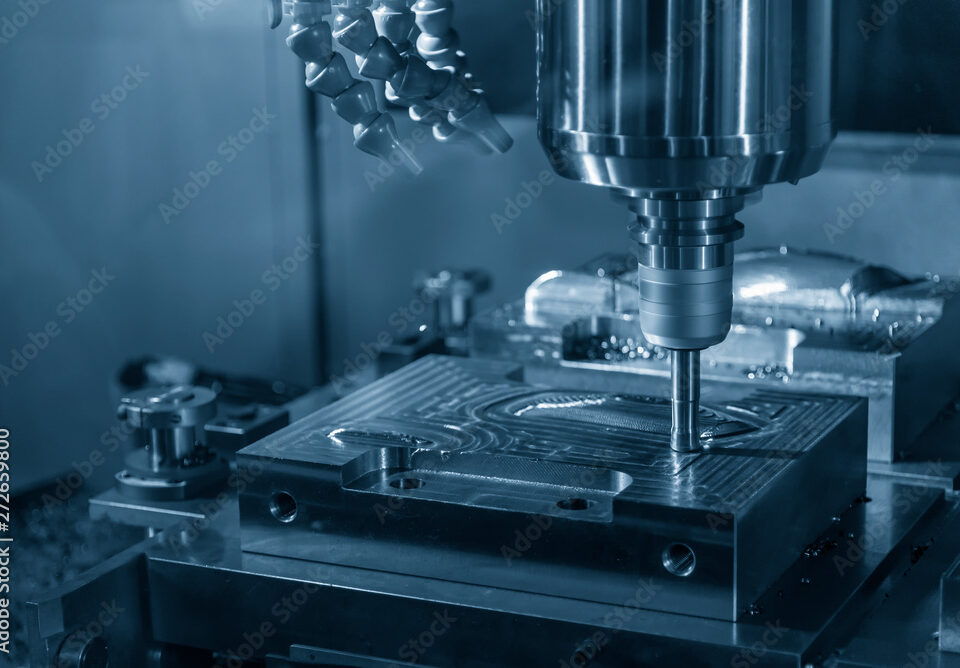

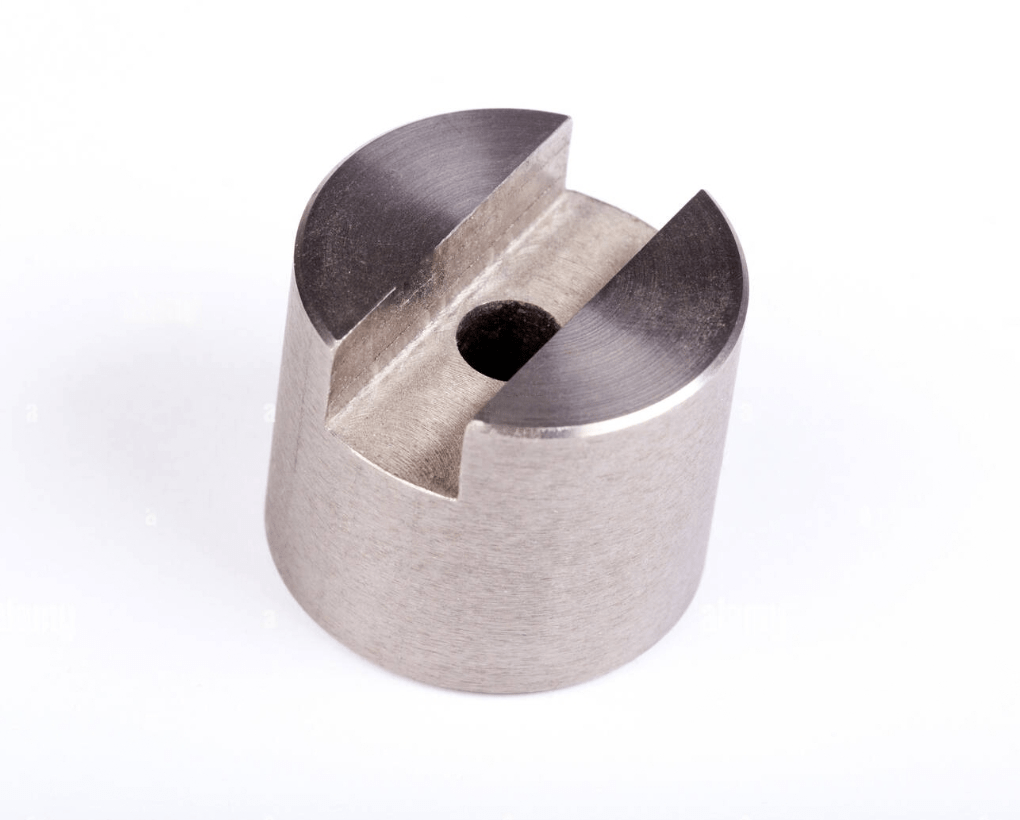

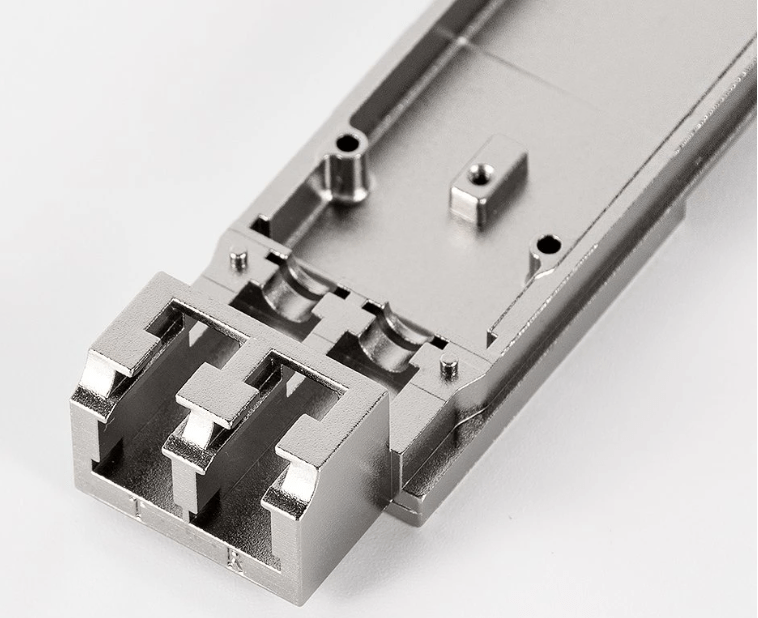

CNC Machining

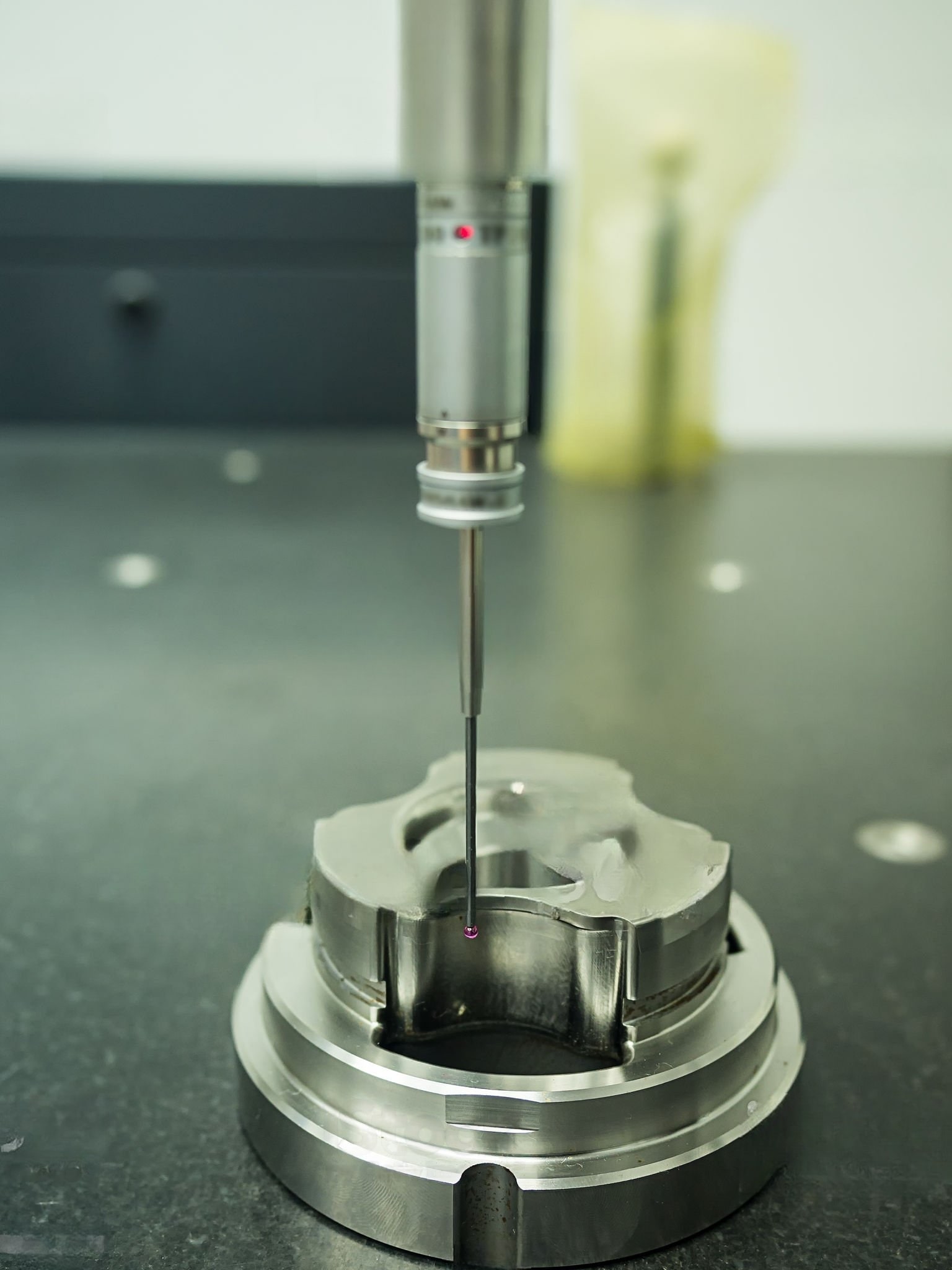

Tolerances as tight as ±0.005mm for meticulous and ultra-precise machining

Advanced CNC machinery with up to 5-axis capabilities, for intricate and complex geometries

Tolerances as tight as ±0.005mm for meticulous and ultra-precise machining

Advanced CNC machinery with up to 5-axis capabilities, for intricate and complex geometries

A Technical Exploration into CNC Machining Precision

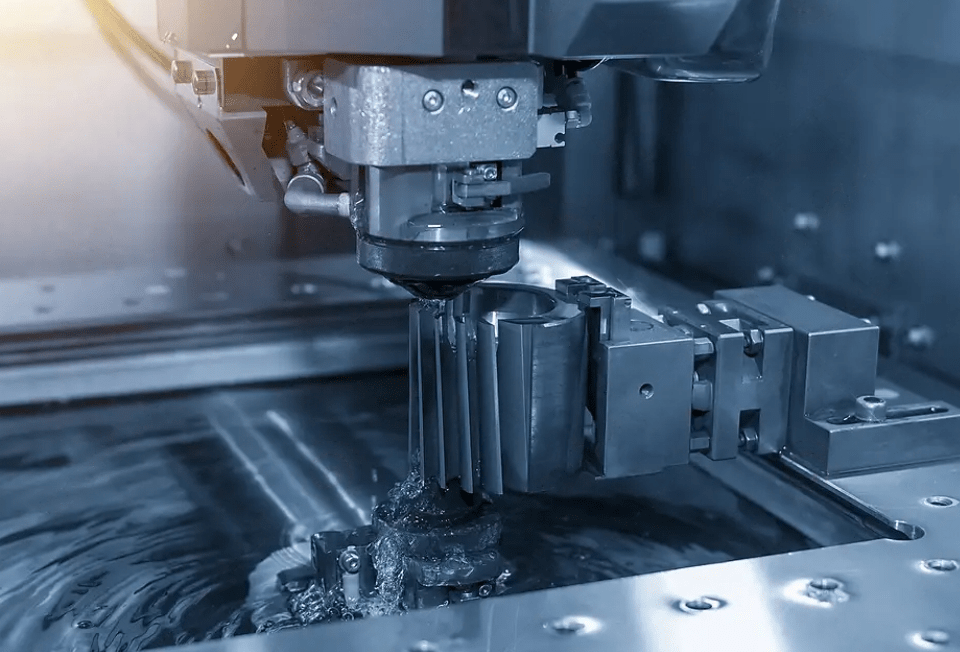

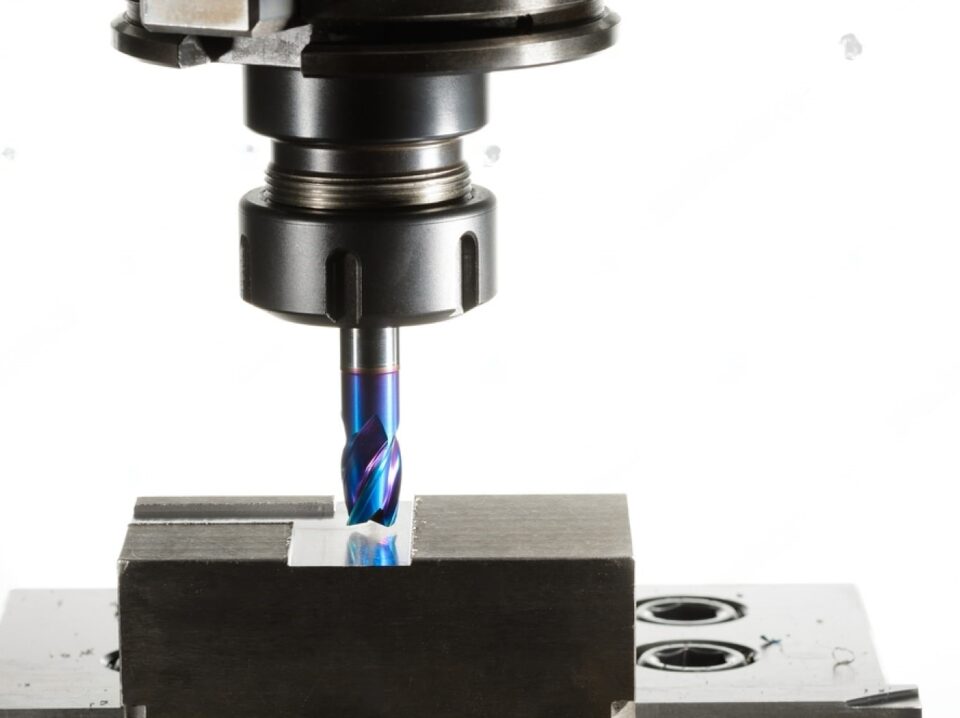

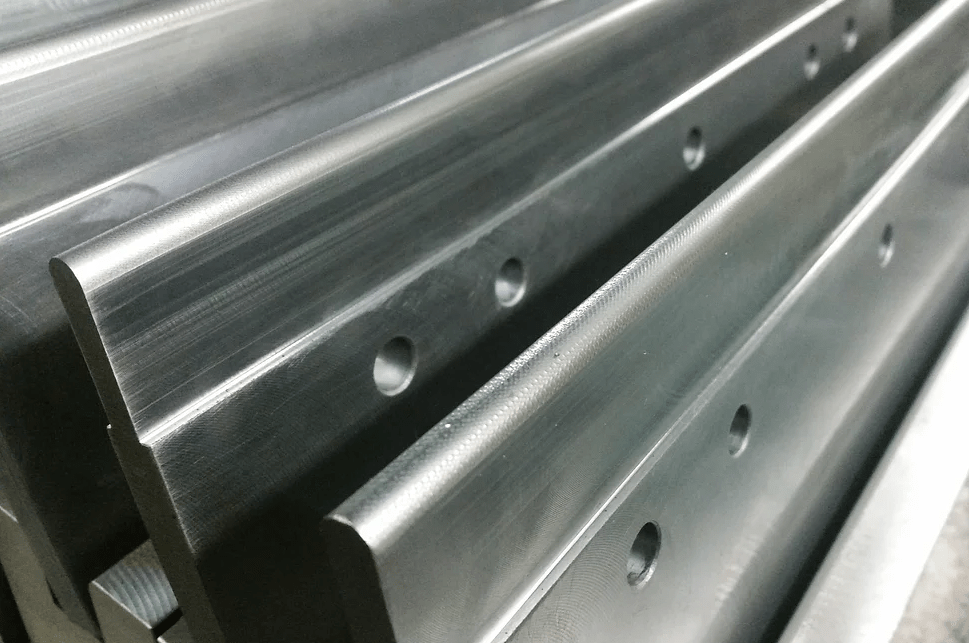

Our CNC machines use advanced software to create precise cuts and shapes, allowing us to produce parts with tolerances as tight as ±0.0002” (±0.00508 mm) to ±0.0005” (±0.0127 mm). We can work with a variety of materials, including aluminum, steel, brass, and more, and can produce complex geometries with ease.

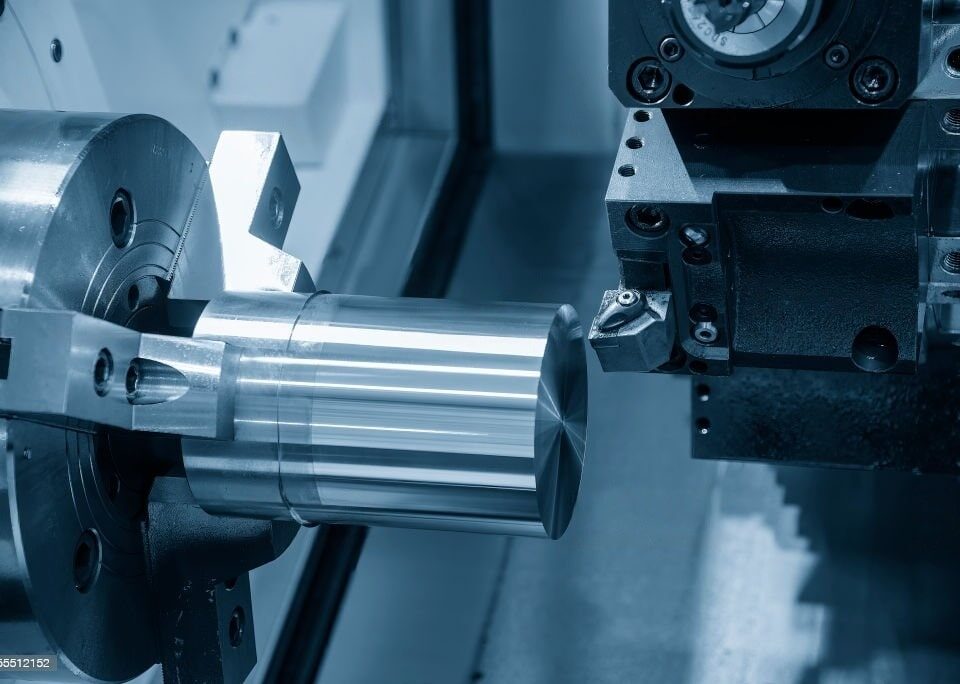

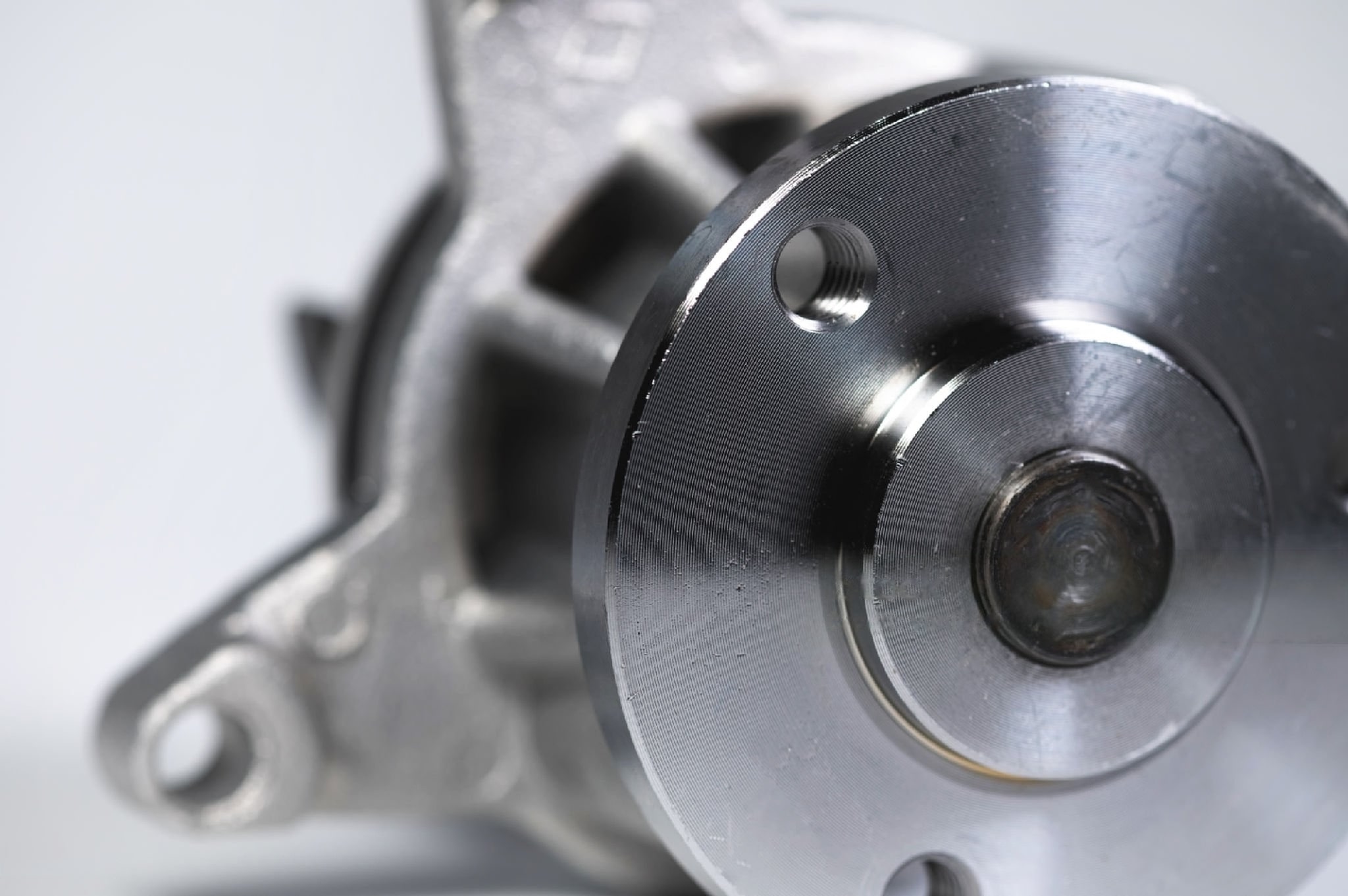

Our advanced CNC turning capabilities allow us to achieve tight tolerances and high precision for cylindrical parts, using a range of materials and finishing options, with the ability to perform both front and back operations on a single chucking.

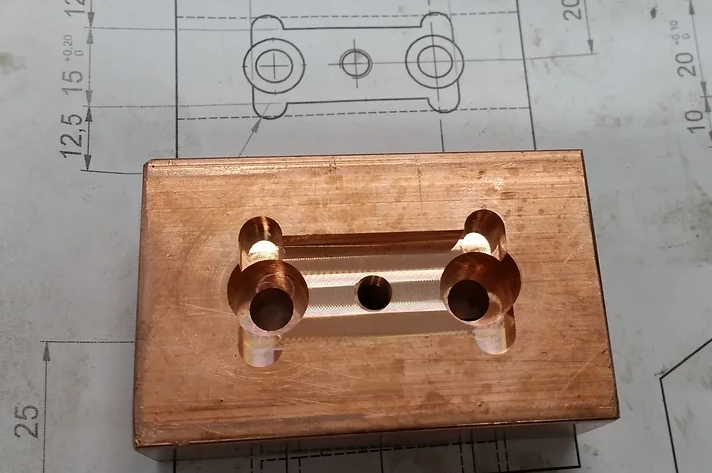

Our EDM service uses a high-precision wire EDM machine capable of cutting complex shapes and fine details with tolerances as tight as +/- 0.0002″, and is suited for machining hard and exotic materials like carbide, titanium, and Inconel.

CNC Machining and Manufacturing services involve the creation of custom-machined parts and components for various industries. This process consists of using various tools and machinery to shape and form metal or other materials to precise specifications.

The importance of this service lies in the fact that many industries rely on these custom parts for the proper functioning of their products and equipment. Machining and manufacturing services typically include a range of processes such as design and engineering, prototyping, precision machining, assembly, and testing. These services are provided by skilled professionals trained in using advanced machinery and tools to produce high-quality parts that meet exacting specifications..

Tailored solutions for industries around the globe

CNC machining services are an essential part of modern manufacturing, enabling the creation of complex parts and components with high precision and accuracy.

CNC or Computer Numerical Control uses computerized tools and machines to automate the process, resulting in faster turnaround times, improved productivity and increased efficiency at its core, CNC machines are computer assisted design (CAD) software is used to create a digital model of a desired part or component . The CAD drawing is then fed into a CNC machine, which uses a variety of cutting tools such as drills, lathes and mills to precisely cut and shape the workpiece.

CNC machining services are used in a wide range of industries, including aerospace, automotive, medical, and electronics. The technology is particularly useful for creating parts with complex geometries or tight tolerances, as well as for producing high volumes of parts with consistent quality.

Our CNC machines are highly automated and offer precision and repeatability, making them ideal for high-volume production runs or complex machining operations. The specific type of machine used will depend on the requirements of the job, including the type of material being machined, the complexity of the part, and the desired level of precision. assembly, and testing.

3000 x 1200 x 850 mm

±0.05mm (metals)

50+ metals

From 4 days

Tolerance Class | Linear Dimention | Hole Diameters | Shaft Diameters |

IT01 | ±0.025 mm | H7: +0.018 mm / +0.050 mm | h6: -0.010 mm / +0.000 mm |

IT0 | ±0.040 mm | H7: +0.021 mm / +0.060 mm | h6: -0.014 mm / +0.004 mm |

IT1 | ±0.080 mm | H7: +0.033 mm / +0.100 mm | h6: -0.025 mm / -0.011 mm |

IT2 | ±0.120 mm | H7: +0.052 mm / +0.130 mm | h6: -0.034 mm / -0.015 mm |

IT3 | ±0.180 mm | H7: +0.084 mm / +0.210 mm | h6: -0.050 mm / -0.022 mm |

Note that these tolerances are based on ISO 2768 mk standards and may vary depending on the specific requirements of a project or industry. Additionally, achieving tight tolerances often requires additional steps or processes, such as inspection and quality control measures. Please consult with Rollmec’s engineering team for specific tolerances for your project.

Quality is of utmost importance to us at Rollmec. We strive to deliver precision and accuracy in all our CNC machining services to ensure our customers’ complete satisfaction.

Our team of experts ensures that every step of the CNC machining process is carried out with the highest quality standards. We employ rigorous quality control measures, including inspection of every part to ensure compliance with customer specifications.

Aluminum is a versatile and widely used material in CNC machined components manufacturing. It is a lightweight metal with a density of approximately 2.7 grams per cubic centimeter (g/cm³), making it about one-third the weight of steel. Despite its low density, aluminum exhibits remarkable strength, especially when alloyed with elements such as copper, magnesium, or zinc.

CCC, Anodizing, Media Blasting, Nickel Plating, Powder Coating, Tumbling, Polishing.

Steel is the most commonly used material in CNC machining, renowned for its strength, versatility, and durability. Steel can vary in composition, resulting in a range of grades with distinct characteristics. Steel offers exceptional mechanical properties, including high tensile strength, which can range from around 300 to 2,000 (MPa), depending on the grade. Its hardness can also be tailored through heat treatment processes. Steel’s excellent machinability allows for precise shaping and fabrication during CNC machining operations.

Low Carbon Steel (AISI 1018)/C15E(1.1141)

Medium Carbon Steel (AISI 1045)/C45E(1.1191)

High Carbon Steel (AISI 1095)/C100S(1.1274)

AISI 4140/42CrMo4 (1.7225) | AISI 4340/34CrNiMo6 (1.6582)

AISI 8620/20NiCrMo2-2 (1.6523)

ASTM A36 / ASTM A105 / ASTM A516

S235JR(1.0038) / S355JR(1.0045)

Black Oxide, Electropolishing, Media Blasting, Nickel Plating, Powder Coating, Tumbling, Polishing, Zinc Plating,

CNC machinists appreciate stainless steel for its machinability and the precise results it offers during manufacturing processes. With its aesthetic appeal, corrosion resistance, mechanical strength, and suitability for diverse applications, stainless steel remains a top material for CNC machining. Its sleek and modern appearance makes it a popular choice for various applications.

Austenitic

304 (1.4301, X5CrNi18-10) | 304L (1.4307, X2CrNi18-9)

316 (1.4401, X5CrNiMo17-12-2) | 316L (1.4404, X2CrNiMo17-12-2)

Ferritic

430 (1.4016, X6Cr17)

Martensitic

410 (1.4006, X12Cr13) | 420 (1.4021, X20Cr13) |416 | 1.4005 | X12CrS13

Duplex

2205 (1.4462, X2CrNiMoN 22-5-3) | 2507 (1.4410, X2CrNiMoN 25-7-4)

Precipitation-hardening

17-4PH (1.4542, X5CrNiCuNb16-4) | 15-5PH (1.4545, X5CrNiCu15-5)

Superaustenitic

904L (1.4539, X1NiCrMoCu25-20-5) | 254SMO (1.4547, X1CrNiMoCuN20-18-7)

Silver

Black Oxide, Electropolishing, Media Blasting, Nickel Plating, Passivation, Powder Coating, Polishing, Zinc Plating, Tumbling(Vibratory)

Tool steel exhibits excellent dimensional stability and resistance to deformation, allowing it to maintain its shape and cutting edge under demanding machining conditions. Its high wear resistance ensures longevity and efficient machining performance. Tool steel’s exceptional heat resistance enables it to withstand elevated temperatures generated during CNC machining operation

AISI D2 (DIN 1.2379)/AISI O1 (DIN 1.2510)/AISI A2 (DIN 1.2363)

AISI S7 (DIN 1.2355)/AISI H13 (DIN 1.2344)/AISI M2 (DIN 1.3343)

AISI M42 (DIN 1.3247)/AISI T1 (DIN 1.3355)AISI D3 (DIN 1.2080)

AISI H11 (DIN 1.2343)/ISI L6 (DIN 1.2714)AISI P20 (DIN 1.2311)

Metallic Grey

Media Blasting, Black Oxide, Powdercoating, Vibratory Tumbling

Cast iron is an alloy of iron, carbon, and other elements, such as silicon and manganese. Its known for its exceptional strength, hardness, and wear resistance, making it suitable for applications that require durability and high load-bearing capacity. Due to its excellent vibration damping properties, cast iron is suitable for components that require reduced noise and vibration levels.

Gray Iron: ASTM A48, A126 / EN-GJL

Ductile Iron: ASTM A536 / EN-GJS

Compacted Graphite Iron (CGI): ASTM A842 / EN-GJV

Malleable Iron: ASTM A47 / EN-GJM

White Iron: ASTM A532 / EN-GJMW

Dull gray, Silver-gray

Tumbling, Media Blasting

Brass is a widely used material in CNC machining due to its excellent combination of properties. It is an alloy primarily composed of copper and zinc, with varying compositions depending on the desired characteristics. In terms of mechanical properties, brass offers good strength, malleability, and ductility. Its machinability is another advantage, as brass can be easily formed, cut, and shaped during CNC machining processes.

Media Blasting, Polishing. Brushing

Copper is an ideal choice for applications that require efficient heat transfer or electrical conduction. With a density of approximately 8.96 (g/cm³), copper is relatively dense. Copper possesses good tensile strength and is highly malleable and ductile. It exhibits exceptional corrosion resistance, especially in atmospheric and marine environments. These properties, along with its antimicrobial qualities, make copper suitable for various CNC machining applications.

As machined, media blasting, polishing.

Titanium is a sought-after material for cnc machining due to its strength and high ductility, allowing for intricate designs. It is a lightweight metal with a remarkable strength-to-weight ratio, weighing about 45% less than steel while maintaining similar strength. It also offers excellent corrosion resistance, even in harsh environments, and is resistant to erosion and fatigue. Titanium’s high melting point of around 1,670°C (3,038°F) makes it suitable for high-temperature applications.

Titanium Grade 1/CP-Ti (Pure Titanium)

Titanium Grade 2/CP-Ti (Pure Titanium)

Grade 5/Ti-6Al-4V

Grade 6/Ti 5Al-2.5Sn

Grade 9/Ti-3Al-2.5V

Grade 12/Ti 3Al 2.5

Media Blasting, Vibratory Tumbling, Passivation, Powder coating

Nickel alloys, such as Inconel and Monel, exhibit exceptional strength, toughness, and resistance to extreme temperatures, making them ideal for demanding CNC machining applications, like aerospace components, marine equipment, chemical processing equipment, and high-temperature applications. Nickel can be machined using various CNC techniques, including milling, turning, and drilling, allowing for the creation of precise and complex parts with excellent dimensional stability.

Inconel 600 (UNS N06600)

Inconel 625 (UNS N06625)

Inconel 718 (UNS N07718)

Inconel 825 (UNS N08825)

Invar 36 (UNS K93600)

Kovar (UNS K94610)

Monel 400 (UNS N04400)

Monel K500 (UNS N05500)

Vibratory Tumbling, Media Blasting, Powdercoating

Magnesium is known for its low density, weighing in at approximately 1.74 grams per cubic centimeter (g/cm³). This characteristic makes it one of the lightest metals employed in structural applications. Despite its feather-light nature, magnesium boasts an impressive strength-to-weight ratio, which contributes to substantial weight reduction across a wide range of uses. For e.g. the AZ91D magnesium alloy, frequently used in CNC machining.

Media Blasting, Powder Coating, Vibratory Tumbling,

Zinc is highly malleable and ductile, allowing for easy shaping, bending, and forming during CNC machining. It also has good thermal and electrical conductivity. Zinc alloys, such as Zamak (a popular zinc alloy), offer enhanced properties and are widely used in CNC machining for various applications, including automotive components, electronic enclosures, decorative hardware, and plumbing fittings.

Media Blasting, Powder Coating, Tumbling

Type | Applicable to | Machining marks | Color | Tolerances | Can be applied with | |

| Anodizing | Aluminum, Titanium | Minimized for non cosmetic, removed on external surfaces for cosmetic | Wide range, customizable | Tolerances are not affected | Media Blasting, Tumbling, CCC* |

| Black Oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible | Black | Met after coating | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | Minimized but visible | Metallic | Met after plating | Media Blasting, Tumbling |

| Electropolishing | Steel, Stainless Steel | Removed on external surfaces | N/A | Met after electropolishing | Always Passivation, Tumbling |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | Removed for non-cosmetic, removed on external surfaces for cosmetic | N/A | Tolerances are not affected | All post processes except Electropolishing and Powder coating |

| Polishing | Aluminum, Stainless Steel, Alloy Steel, Brass, Bronze, Copper | Removed on external surfaces | N/A | Met after polishing | Used for cosmetic appearances |

| Nickel Plating | Aluminum, Steel, Stainless Steel | Minimized for non cosmetic, removed on external surfaces for cosmetic | N/A | Met after plating | Media Blasting, Tumbling |

| Passivation | Steel, Stainless Steel | Minimized but visible | N/A | Tolerances are not affected | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

| Powder Coating | Aluminum, Steel, Stainless Steel | Minimized for non cosmetic, removed on external surfaces for cosmetic | standard colors, metallic finishes | Normally met after Coating | Media Blasting, Tumbling |

| Chromate conversion coating | Aluminum | Visible | Clear, gold | Tolerances are not affected | Media Blasting, Tumbling, Type II /Type III Anodizing*, Type III Anodizing with PTFE* |

| Tumbling | Aluminum, Steel, Stainless Steel | Minimized but visible | standard colors, metallic finishes | Slightly affected after tumbling | All post processes except Electropolishing and Powder coating |

| Zinc Plating | Steel, Stainless Steel | Minimized visibility on a substrate | Clear: light blue coating, black: glossy black coating | Met after plating | Media Blasting, Tumbling, Passivation |

CNC machining is a revolutionary technology that enables manufacturers to achieve high levels of precision and accuracy in their production processes.

Our CNC machines are capable of machining complex shapes and contours, supported by the latest CAD and CAM software, allowing us to produce components with exceptional accuracy and efficiency.

One of the key advantages of CNC machining is its exceptional precision and accuracy. CNC machines can achieve incredibly tight tolerances, ensuring that each produced part meets the exact specifications required. This level of precision eliminates human error and guarantees consistent quality throughout the production process.

CNC machining is highly efficient and significantly faster than traditional manufacturing methods. Once the program is set, CNC machines can operate continuously, 24/7, without the need for constant human supervision. This increased productivity results in shorter lead times and faster delivery of finished products.

CNC machines offer exceptional versatility and flexibility. They can be programmed to produce an extensive range of complex shapes, from simple geometries to intricate designs. Moreover, CNC machines can easily switch between different manufacturing tasks, allowing manufacturers to adapt to changing production requirements quickly.

CNC machining is ideal for repetitive production tasks. Once a program is created and verified, CNC machines can reproduce the same part repeatedly with absolute consistency. This capability is especially valuable for mass production, ensuring that every item meets the same high-quality standards.

Yes, CNC machining is an excellent choice for prototyping due to its ability to quickly produce accurate and complex parts. It allows for rapid iterations and modifications to the design.

Yes, CNC machining is capable of handling large-scale production. With the right setup, multiple CNC machines can work in parallel, ensuring high productivity and efficient manufacturing processes.

CNC machining is known for its exceptional accuracy. Depending on the machine’s capabilities and the tolerances required, CNC machining can achieve precision up to a few microns.

Yes, CNC machines can work with a wide variety of materials, including metals (such as aluminum, steel, and titanium), plastics, wood, composites, and more.

The cost of CNC machining depends on various factors, including the complexity of the part, material selection, machine setup time, and tooling costs. While CNC machining can be cost-effective for high-volume production, it may not be suitable for small-scale or one-off projects.

While CNC machining offers numerous advantages, it does have limitations. It may not be suitable for extremely large parts or those with intricate internal features that cannot be accessed by cutting tools. Additionally, the initial setup and programming time can be time-consuming for small production runs.