QualityQuality Standards in Robotics & Automation

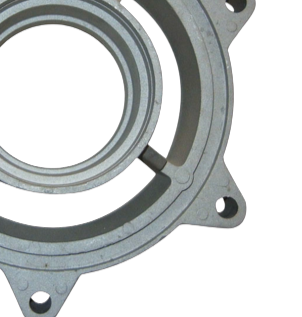

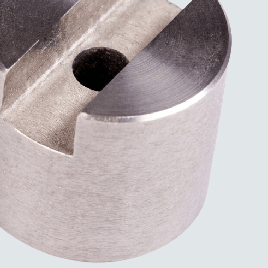

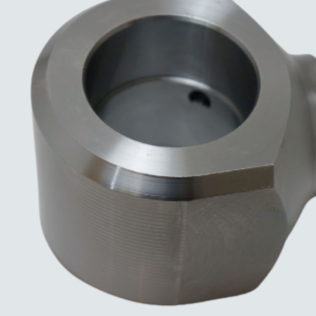

Crafting precision components for the Robotics and Automation industry isn’t just about meeting standards, it’s about setting them. At Rollmec, our quality control is the cornerstone of our operation. We ensure that every component we produce not only meets but exceeds industry standards. Here’s how we achieve that

Precise adherence to tight tolerances ensures that our components consistently perform within the specified limits, crucial for maintaining the integrity of robotics and automation systems.

Our ISO 9001 certification demonstrates our commitment to adhering to internationally recognized quality management standards, assuring customers of our dedication to quality assurance.

Rigorous durability testing, including accelerated wear and tear simulations, ensures that our components can withstand the demands of continuous operation in automated systems.

Our meticulous record-keeping and traceability processes guarantee that every component can be traced back to its source, ensuring consistent quality and easy issue identification.

Adherence to environmental regulations ensures that our manufacturing processes are environmentally responsible while maintaining product quality and safety.