Quality AssuranceMeticulous Precision - Our Quality Code

Uncover the symphony of precision that defines Rollmec’s quality assurance

ISO 9001:2015 Certified

+300K Parts Inspected

Tolerances down to ±0.0004 (0.01mm)

Need of high accuracy and reliability

When it comes to precision machined components, the stakes are even higher. These components are used in a wide range of industries, from aerospace to medical devices, and they must meet strict tolerances and quality standards. At Rollmec, we take care of the critical aspects of quality assurance for precision machined components, ensuring that every product leaving the production line is of the highest quality. We adhere to the rigorous standards outlined in our ISO 9001:2015 certification, ensuring every facet of our manufacturing process is finely tuned to exceed industry expectations

Benefits The Importance of Quality Inspection

Quality inspection is a critical step in the CNC machining process. It ensures that the parts produced meet the required specifications and adhere to industry standards. Let’s explore why quality inspection is so vital:

Meeting Tolerances

One of the primary goals of quality assurance in precision machining is to ensure that the components meet the specified tolerances. Even the slightest deviation can result in catastrophic failures in the systems where these parts are used.

Ensuring Durability

Precision machined components must withstand harsh conditions. Quality assurance processes include testing the materials for durability and longevity

Detecting defects early in the manufacturing process can save a considerable amount of money. It is far more cost-effective to identify and rectify issues during inspection than to discover them after the parts are assembled into the final product.

Different industries have specific quality standards that must be met. Quality inspection ensures that the CNC machined parts adhere to these standards, making them safe and reliable for their intended use.

Precision Calibration

Mastery

Each component undergoes a rigorous calibration routine, ensuring exact measurements and adherence to the most stringent industry specific quality standards.

Dimensional Consistency Assurance

Through rigorous testing and inspection, we guarantee that every part meets the exact specifications, providing reliability and ease of integration for our clients.

Innovative Material

Durability

By employing innovative alloys and materials science, we enhance the lifespan of our precision components, ensuring they withstand the harshest conditions.

Strategic Quality Partnerships

Collaborating with renowned certification bodies and experts in the field, we continuously refine our quality processes, staying ahead of industry standards

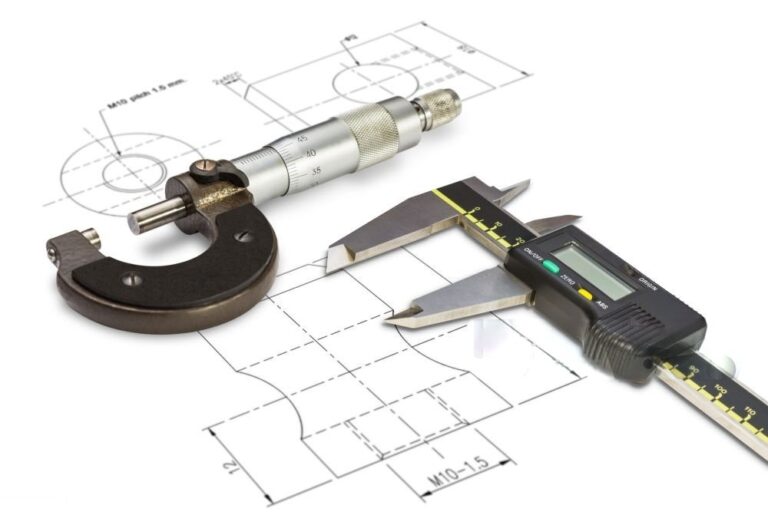

Our Precision Measurement Arsenal

In CNC machining, our precise measurement instruments uphold the highest standards, ensuring accuracy and reliability through meticulous measurements.

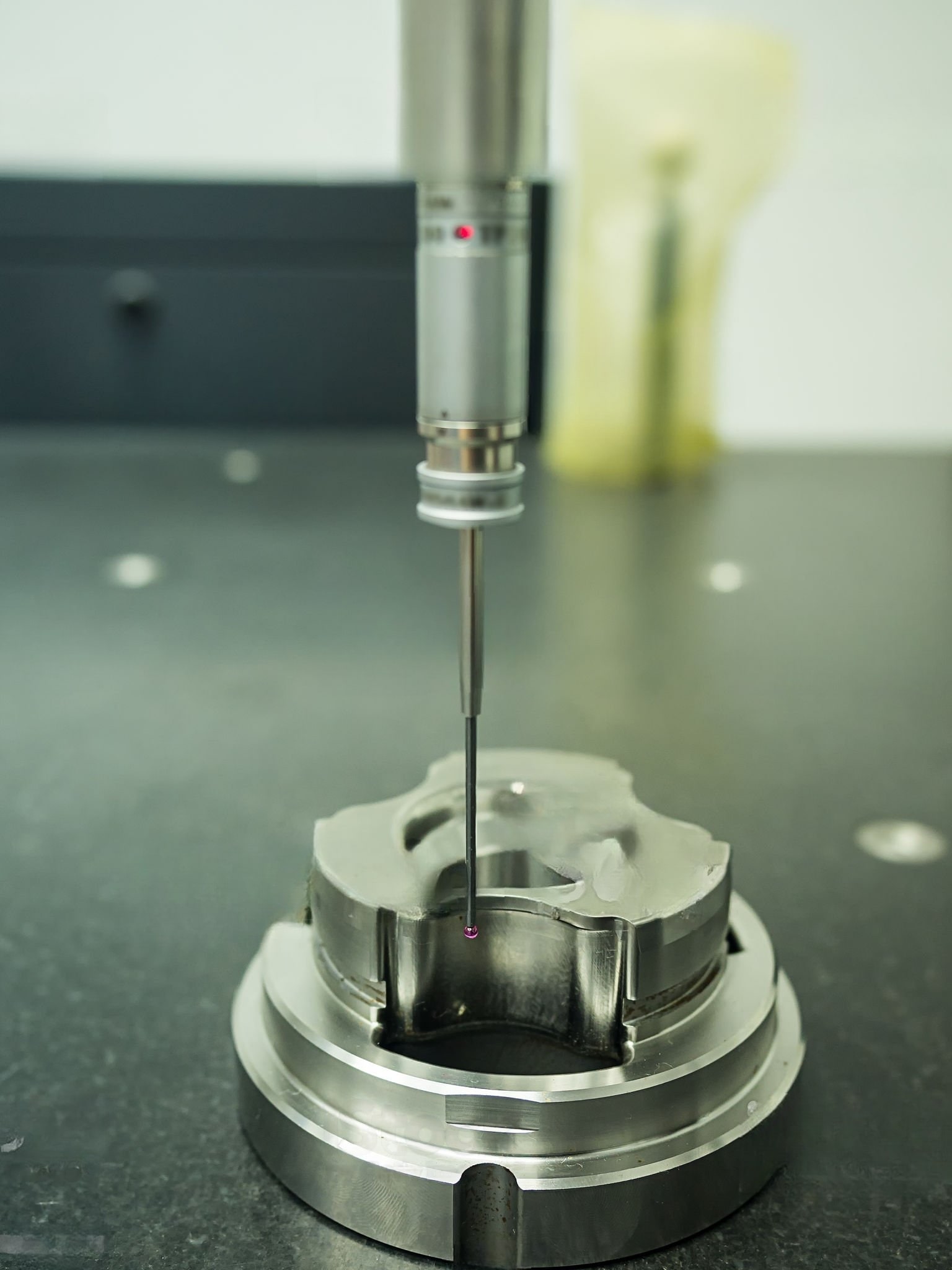

Coordinate Measuring Machine

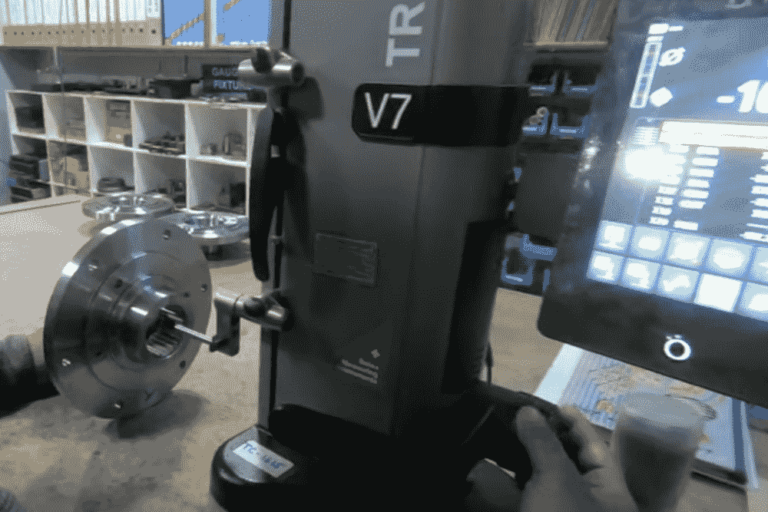

Roundness Measurement System

In-process Inspection

Hardness Testing Devices

Height Gauge Vertical 2D

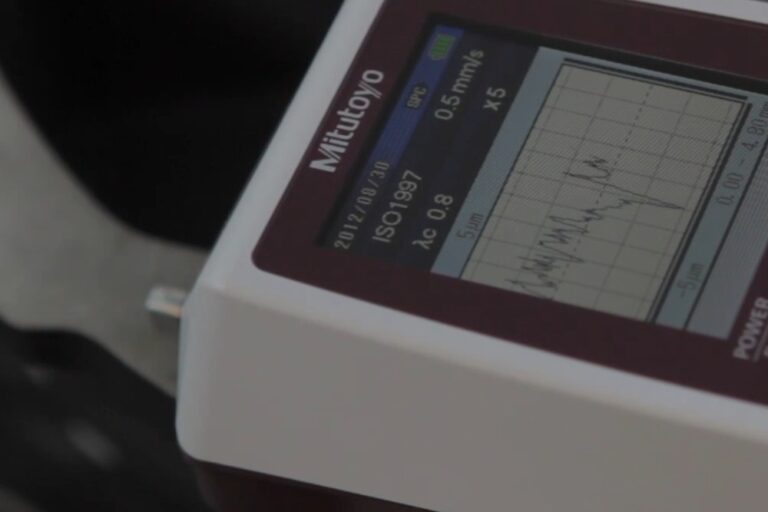

Surface Roughness Tester

How it worksQuality inspection process

of our CNC machined parts

Visual Inspection

Dimensional Measurement

Material Verification

Surface Finish Evaluation

Tolerances and Fits

Functional Testing

Documentation

Services Our Complete Machined Parts Inspection Services

- Dimensional Inspection

- Surface Finish Analysis

- Material Testing

- Tolerance Verification

- Visual Inspection

- (GD&T) Analysis

- Non-Destructive Testing (NDT)

- Statistical Process Control (SPC)

- First Article Inspection (FAI)

- In-Process Inspection

- Final Inspection

- (CAPA) Implementation

Reliable solutions for industries across the globe

CertificateAdherence to ISO 9001:2015 Standards

Rollmec proudly upholds the ISO 9001:2015 certification, underscoring our unwavering commitment to quality and customer satisfaction

This internationally recognized certification mandates stringent standards for quality management systems, ensuring meticulous attention to detail, continuous improvement, and risk mitigation across every facet of our operations.

Rigorous Quality Management Standards

Continuous Improvement Framework

Systematic Process Monitoring

Consistent Adherence to Industry Benchmarks

Client-Centric Quality Commitments

Quality Issue Resolution

Quality Report Insights

On-site Visitation

Confidentiality and NDA

General FAQs

Yes, defects can be identified and corrected during the inspection process, saving time and costs

CNC machining, combined with quality inspection, helps detect defects early, reducing the cost of rework and ensuring that the final product meets the required standards.

Rollmec maintains consistent quality through methods like Statistical Process Control (SPC), skilled workforces, and using high-precision machines to ensure accuracy in every component we produce.

Material selection is pivotal in ensuring durability and longevity of precision machined components. Using the right material can prevent premature wear and tear

Technology has greatly improved quality assurance through advanced equipment like 3D scanning and non-destructive testing methods, which provide more accurate and efficient inspection processes.

Continuous improvement is essential to stay at the forefront of quality standards. Methods like Six Sigma and Lean Manufacturing help manufacturers identify and rectify issues, ensuring constant enhancement in quality