QualityPump and Valve Components with Unyielding Quality

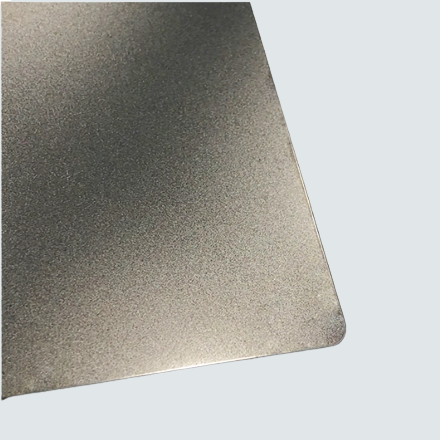

Each component is subjected to rigorous testing procedures to confirm material integrity. Pressure and flow testing further validate the performance under various operational conditions, from high pressures to extreme temperatures. Our comprehensive documentation, providing full material traceability and certifications that align with industry-specific standards such as ASTM, ASME, and API.

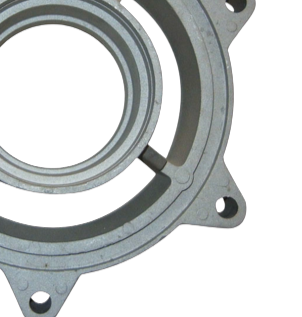

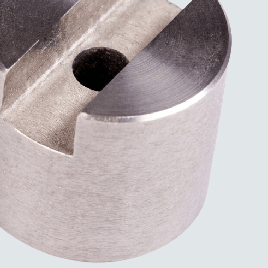

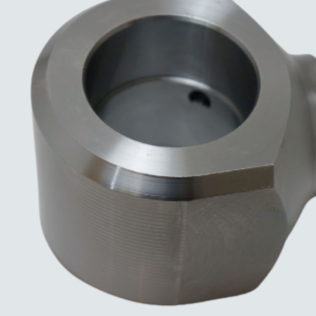

Our components are crafted with precision machining techniques that guarantee tight tolerances, ensuring optimal performance and leak-free operation in demanding fluid control systems.

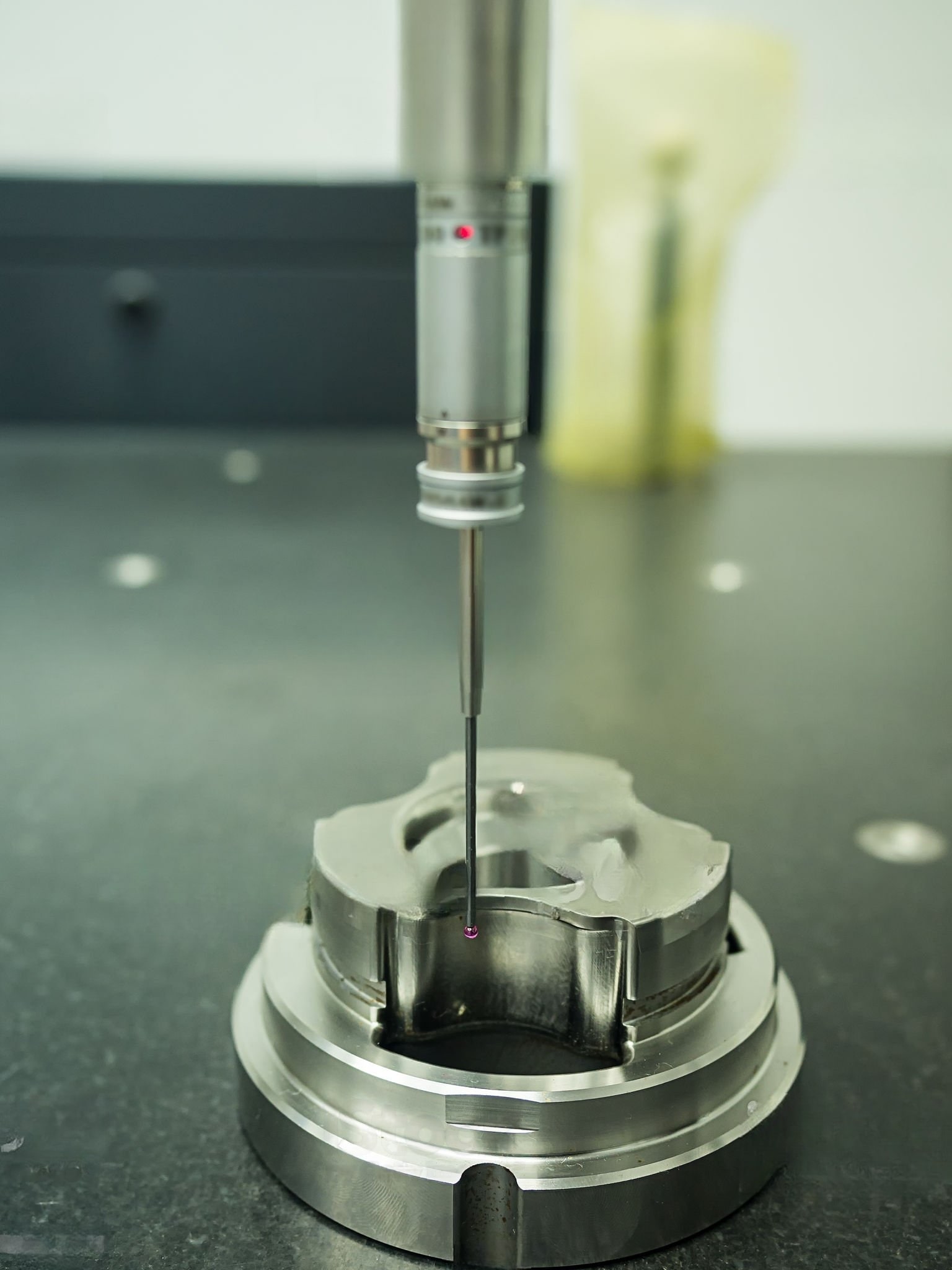

Each component undergoes rigorous inspection and testing processes. From non-destructive testing for material integrity to pressure and flow testing for performance validation, we leave no stone unturned in ensuring the reliability of our products.

We provide comprehensive documentation and certification for each component, allowing you to trace the quality assurance process and verify compliance with industry standards.

Our components meet ASTM, ASME, and other relevant standards, ensuring compatibility and reliability in a wide range of applications.