QualityExemplary Quality Assurance in the Automotive Sector

Superior quality in medical component manufacturing is deeply rooted in our meticulous, technically-driven approach. We use advanced practices, precision, and methodologies, while rigorously adhering to industry regulations. When you choose Rollmec, you can have complete confidence that your medical components will consistently surpass the highest quality and precision standards throughout the entire manufacturing process.

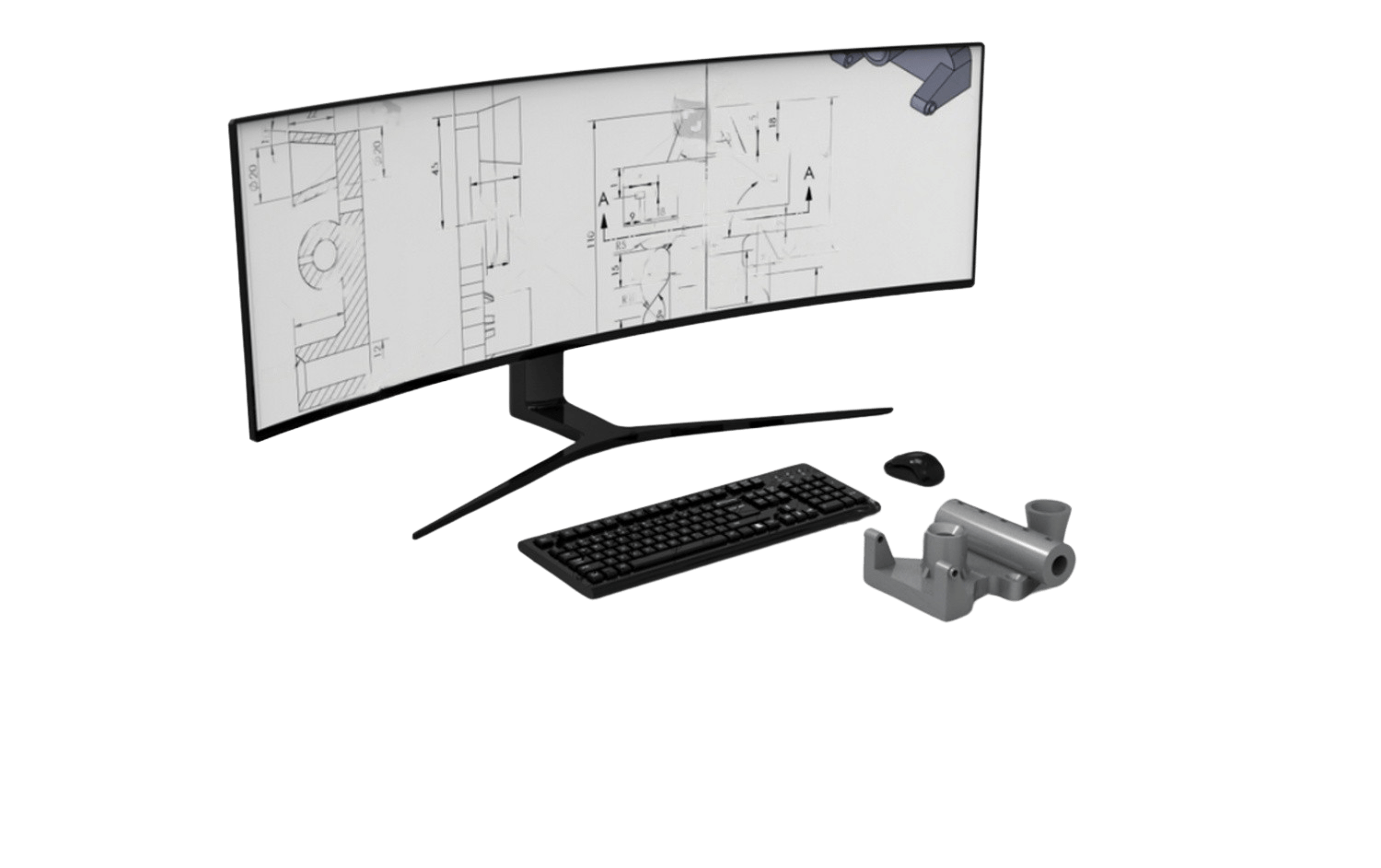

Our manufacturing process incorporates Statistical Process Control methods, where we continuously monitor and analyze process variables. By applying SPC, we maintain tight control over critical parameters, ensuring that each component is produced with exceptional precision and consistency.

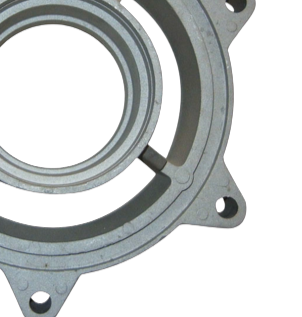

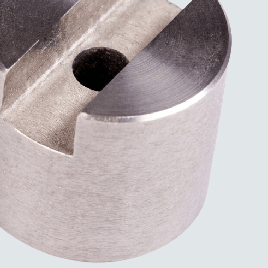

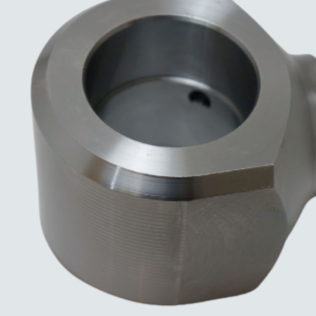

We utilize cutting-edge inspection equipment, such as coordinate measuring machines (CMMs) and optical inspection systems, to meticulously assess the dimensions and tolerances of each component. This ensures that every part meets the precise specifications required for medical applications.

Rollmec has a risk-based quality management approach, focusing on comprehensive risk assessments and mitigation strategies. This ensures that potential quality issues are identified early and addressed, reducing the likelihood of component failures and enhancing overall product reliability.

We subject every medical component to extensive testing and validation procedures, including functional testing, stress testing, and biocompatibility testing. This ensures that your components perform reliably and safely in real-world medical applications.

Our quality control processes are tightly aligned with medical device regulations and standards. This includes adherence to FDA 21 CFR Part 820, ISO 13485, and specific requirements set by other regulatory bodies. We maintain the necessary documentation and processes to facilitate regulatory compliance, ensuring that your components are market-ready from a quality and regulatory perspective.