QualityQuality Assurance in Industrial Machinery Manufacturing

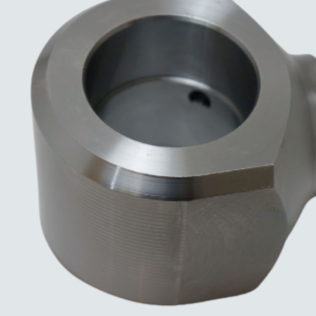

Our quality, precision, and durability sets us apart in machining technologies, optimizing tolerance levels to the micron, guaranteeing the precise fit and functional integrity of each component within complex machinery systems. Our metallurgical experts meticulously design and treat materials, tailoring alloy compositions and heat treatments to ensure superior strength, corrosion resistance, and extended fatigue life

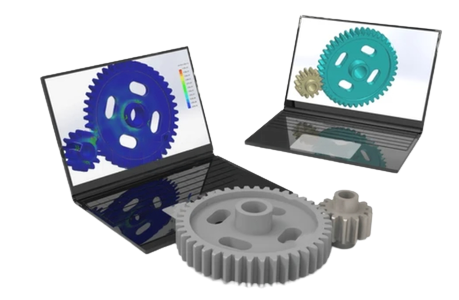

Components undergo thorough dynamic load analysis to assess their capacity to withstand stress and cyclic loading, ensuring reliability in heavy-duty machinery applications.

We implement SPC techniques to monitor the manufacturing process continuously, allowing for immediate adjustments to maintain consistency and precision.

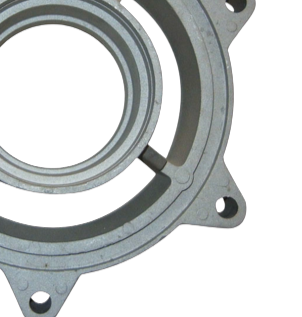

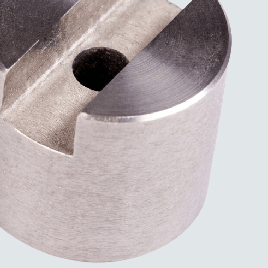

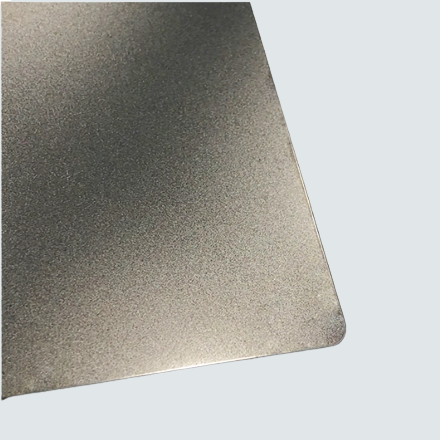

Our surface treatments, such as hardening, coatings, and finishes, enhance wear resistance and reduce friction, extending the operational life of industrial machinery components.

Through the implementation of specialized damping materials and structural designs, we mitigate vibrations and resonance that can cause premature component failure and ensure stable machinery operation.

We employ advanced machining techniques to achieve tight tolerances, ensuring that components fit precisely and function flawlessly within industrial machinery, reducing wear and tear.