QualityQuality and Precision for Consumer Products

Our quality assurance protocols encompass a range of technical features tailored to meet the unique demands of consumer products. We meticulously control dimensional precision, material traceability, and conduct rigorous quality control testing, encompassing tensile strength, hardness, and thermal resistance, to ensure that our components meet and exceed the expectations of the consumer product industry

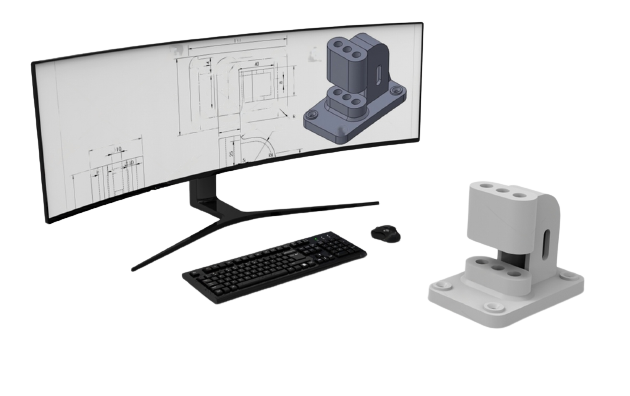

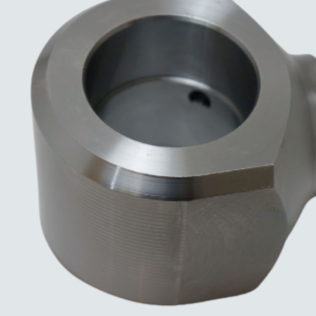

We use advanced metrology tools to guarantee that every consumer product component adheres to precise dimensional specifications, ensuring seamless integration within your product.

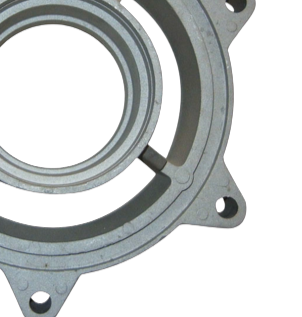

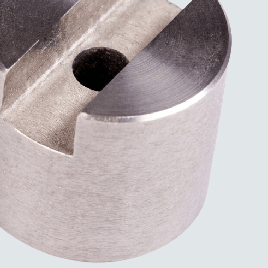

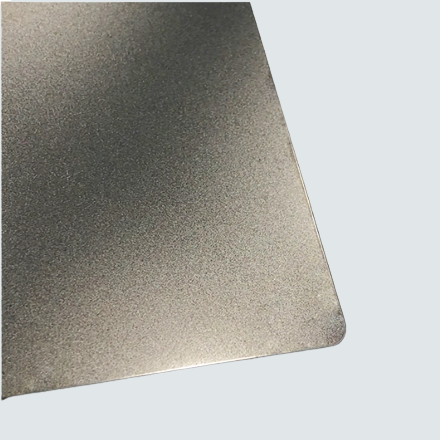

We pay close attention to surface finishes, achieving the desired texture, smoothness, and appearance, which not only enhances the aesthetics of consumer products but also contributes to their functionality and durability.

For consumer product components that may encounter various environmental conditions, we conduct corrosion resistance testing to ensure that the components can withstand prolonged exposure to moisture, chemicals, and other potential corrosive elements, making them suitable for long-lasting use.

Our ethos of perpetual improvement means we are consistently refining and optimizing our manufacturing processes, exceeding consumer product standards and delivering components that augment the efficiency, dependability, and longevity of your products. With Rollmec, quality is not just a promise; it’s a technical benchmark we exceed with each component we produce.