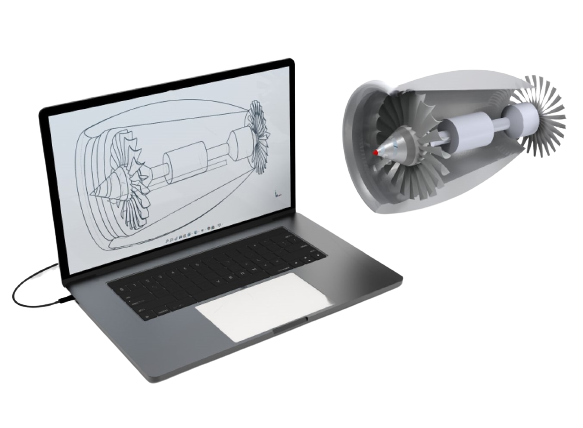

QualityAerospace components that meet the highest industry standards

We adhere rigorously to the stringent standards set forth in aerospace and aviation component manufacturing, ensuring precision and reliability in every facet of our production. From material selection to final inspection, our dedicated team ensures compliance with AS9100 and ISO 9001 certifications. Our quality assurance protocols encompass

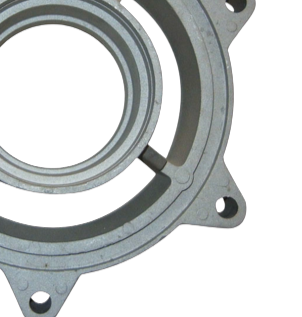

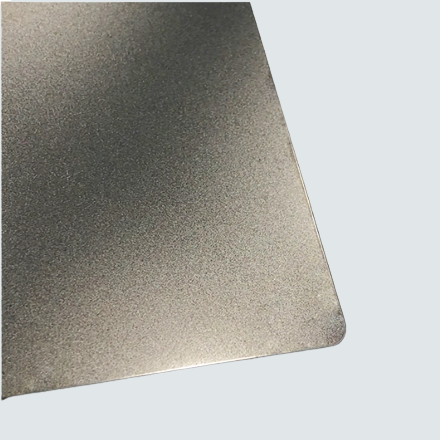

Thorough examination of material properties to meet exacting requirements

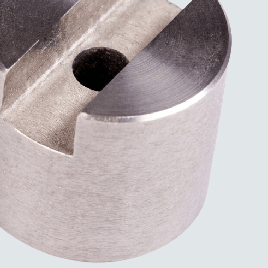

Employing cutting-edge NDT methods for flaw detection

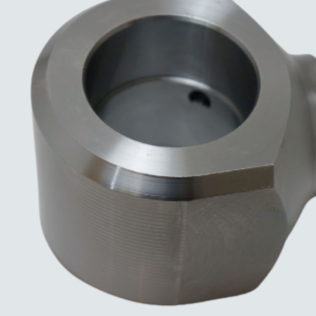

Precision machining and measurement to uphold meticulous tolerances

Comprehensive documentation for every component’s origin and processes

Rigorous trials to ensure optimal performance under demanding conditions